In the realm of electrical installations, efficiency, organization, and safety are paramount. One often-overlooked yet crucial component in this domain is the humble cable tray. From industrial complexes to commercial buildings, cable trays play a significant role in supporting and organizing cables, ensuring a seamless flow of power and data. Let’s delve into what cable trays are, their types, advantages, applications, installation processes, maintenance tips, and future trends.

Introduction to Cable Trays

What are cable trays?

Cable trays are structural systems used to support insulated electrical cables used for power distribution, communication, and control. They provide a secure pathway for cables while facilitating easy installation and maintenance.

Importance of cable trays in electrical installations

In any electrical setup, the organization of cables is critical for efficient operation and maintenance. Cable trays offer a solution by providing a structured framework for routing and supporting cables, thus minimizing the risk of cable damage and electrical hazards.

Types of Cable Trays

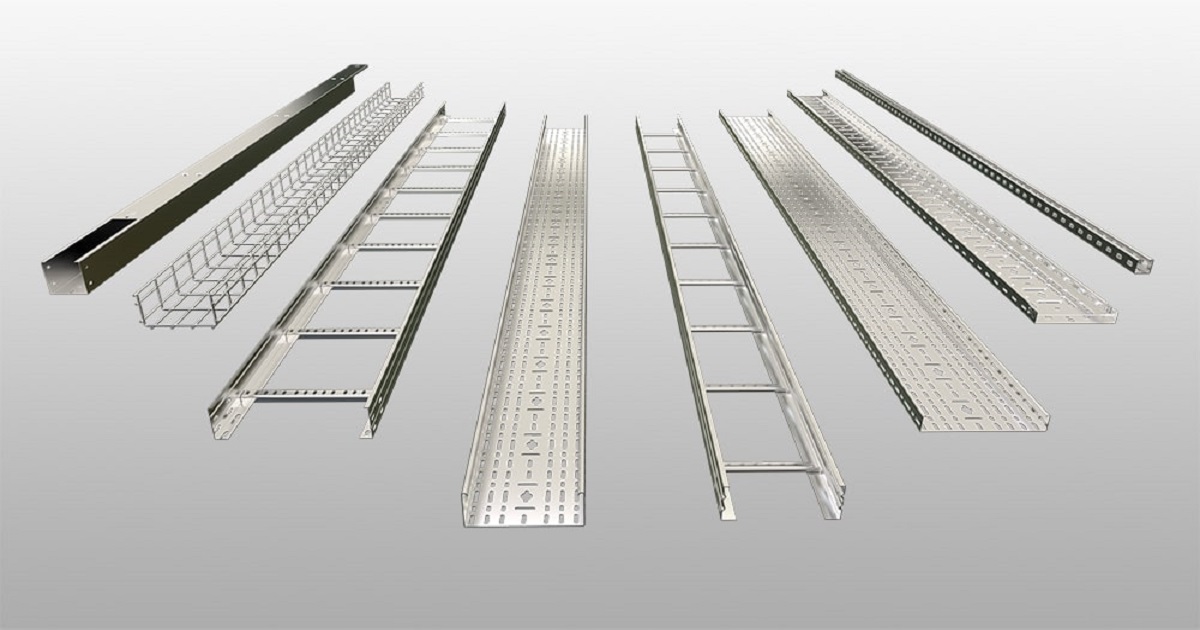

There are several types of cable trays available, each designed to meet specific requirements:

Ladder trays

Ladder trays consist of two longitudinal side rails connected by individual transverse members, resembling a ladder. They offer excellent ventilation and are ideal for heavy-duty applications.

Perforated trays

Perforated trays feature a series of perforations along their length, allowing for better airflow and drainage. They are suitable for applications where ventilation is crucial.

Solid bottom trays

Solid bottom trays have a solid base, providing maximum protection for cables against dust, moisture, and other environmental factors. They are commonly used in harsh industrial environments.

Wire mesh trays

Wire mesh trays are constructed from welded wire mesh panels, offering high strength and flexibility. They are lightweight and easy to install, making them suitable for a wide range of applications.

Advantages of Cable Trays

Versatility

Cable trays are incredibly versatile and can accommodate various types of cables, including power, data, and control cables. They can also be easily customized to fit specific requirements.

Cost-effectiveness

Compared to traditional conduit systems, cable trays are more cost-effective, both in terms of material and labor costs. Their modular design allows for quick installation and scalability.

Easy installation and maintenance

Installing cable trays is relatively straightforward, requiring minimal specialized tools or equipment. Additionally, their open design makes inspection and maintenance tasks hassle-free.

Applications of Cable Trays

Cable trays find applications across various industries and settings, including:

Industrial applications

In industrial settings such as manufacturing plants and refineries, cable trays are used to route and support cables in harsh environments.

Commercial buildings

In commercial buildings like office complexes and shopping malls, cable trays provide a neat and organized solution for managing electrical wiring.

Data centers

In data centers where the reliability and efficiency of electrical systems are critical, cable trays play a crucial role in ensuring seamless operation.

Factors to Consider When Choosing Cable Trays

When selecting cable trays for a particular application, several factors need to be taken into account, including:

Load capacity

The cable tray must be able to support the weight of the cables it carries, along with any additional loads such as snow or wind.

Environmental factors

Consideration should be given to the environmental conditions in which the cable tray will be installed, including temperature extremes, humidity, and exposure to corrosive substances.

Corrosion resistance

In corrosive environments such as chemical plants or coastal areas, choosing corrosion-resistant materials for the cable trays is essential to ensure longevity.

Installation Process of Cable Trays

Proper installation of cable trays is crucial for their effectiveness and longevity. The installation process typically involves:

Planning and design

Before installation, a thorough assessment of the site and cable routing requirements should be conducted to determine the optimal placement and configuration of the cable trays.

Mounting the trays

Once the design is finalized, the cable trays are mounted on suitable supports such as walls, ceilings, or floor-mounted brackets, ensuring proper alignment and spacing.

Cable laying

After the trays are installed, cables are laid inside them according to the pre-determined routing plan, taking care to maintain proper segregation and bundling.

Maintenance Tips for Cable Trays

Regular maintenance is essential to ensure the continued performance of cable trays. Some maintenance tips include:

Regular inspections

Periodic inspections should be carried out to check for signs of damage, corrosion, or loose connections.

Cleaning and debris removal

Cable trays should be kept clean and free from debris to prevent blockages and potential fire hazards.

Repair and replacement

Any damaged or worn-out components should be promptly repaired or replaced to prevent further deterioration.

Safety Precautions When Working with Cable Trays

Working with electrical systems, including cable trays, poses inherent risks. To ensure safety, it’s essential to:

Proper grounding

Ensure that the cable trays are properly grounded to prevent the risk of electric shock or fire.

Avoiding overloading

Never overload the cable trays beyond their specified load capacity to prevent structural failure and potential accidents.

Following installation guidelines

Adhere to the manufacturer’s installation guidelines and industry standards to ensure safe and proper installation of cable trays.

Future Trends in Cable Tray Technology

As technology advances, so do cable tray systems. Some emerging trends in cable tray technology include:

Integration with smart systems

Cable trays equipped with sensors and monitoring devices enable real-time monitoring of cable health and performance, allowing for predictive maintenance and improved reliability.

Enhanced durability and efficiency

Advancements in materials and manufacturing techniques are leading to the development of cable trays that offer increased durability, corrosion resistance, and energy efficiency.

Conclusion

Cable trays are an integral part of modern electrical installations, offering a reliable and efficient solution for cable management. By understanding the different types of cable trays, their advantages, applications, and installation requirements, electrical professionals can ensure safe and effective deployment of these essential components.

FAQ

- What materials are cable trays made of? Cable trays can be made from various materials, including steel, aluminum, and fiberglass, depending on the application and environmental requirements.

- Can cable trays be used outdoors? Yes, cable trays can be used outdoors, provided they are made from weather-resistant materials and designed to withstand outdoor conditions.

- How do cable trays compare to conduit systems? Unlike conduit systems, which enclose cables in rigid tubes, cable trays offer an open design that allows for easier installation, inspection, and maintenance.

- Are there regulations governing the installation of cable trays? Yes, there are industry standards and regulations that govern the design, installation, and maintenance of cable trays, ensuring safety and compliance with building codes.

- Can cable trays accommodate different types of cables? Yes, cable trays are designed to accommodate various types of cables, including power, data, and control cables, providing versatility and flexibility in electrical installations.