Ferritik stainless steel, known for its exceptional wear resistance properties, stands out among various stainless steel types for its durability and reliability in demanding applications. In this article, we delve into the unique characteristics of ferritik stainless steel that set it apart from other types, such as austenitic and martensitic stainless steel.

By exploring the factors contributing to its superior wear resistance and examining its applications across industries, we aim to provide a comprehensive understanding of why ferritik stainless steel is a preferred choice for challenging environments. Furthermore, we will discuss future prospects and innovations in ferritik stainless steel technology, highlighting advancements that continue to enhance its performance capabilities.

1. Introduction to Ferritik Stainless Steel

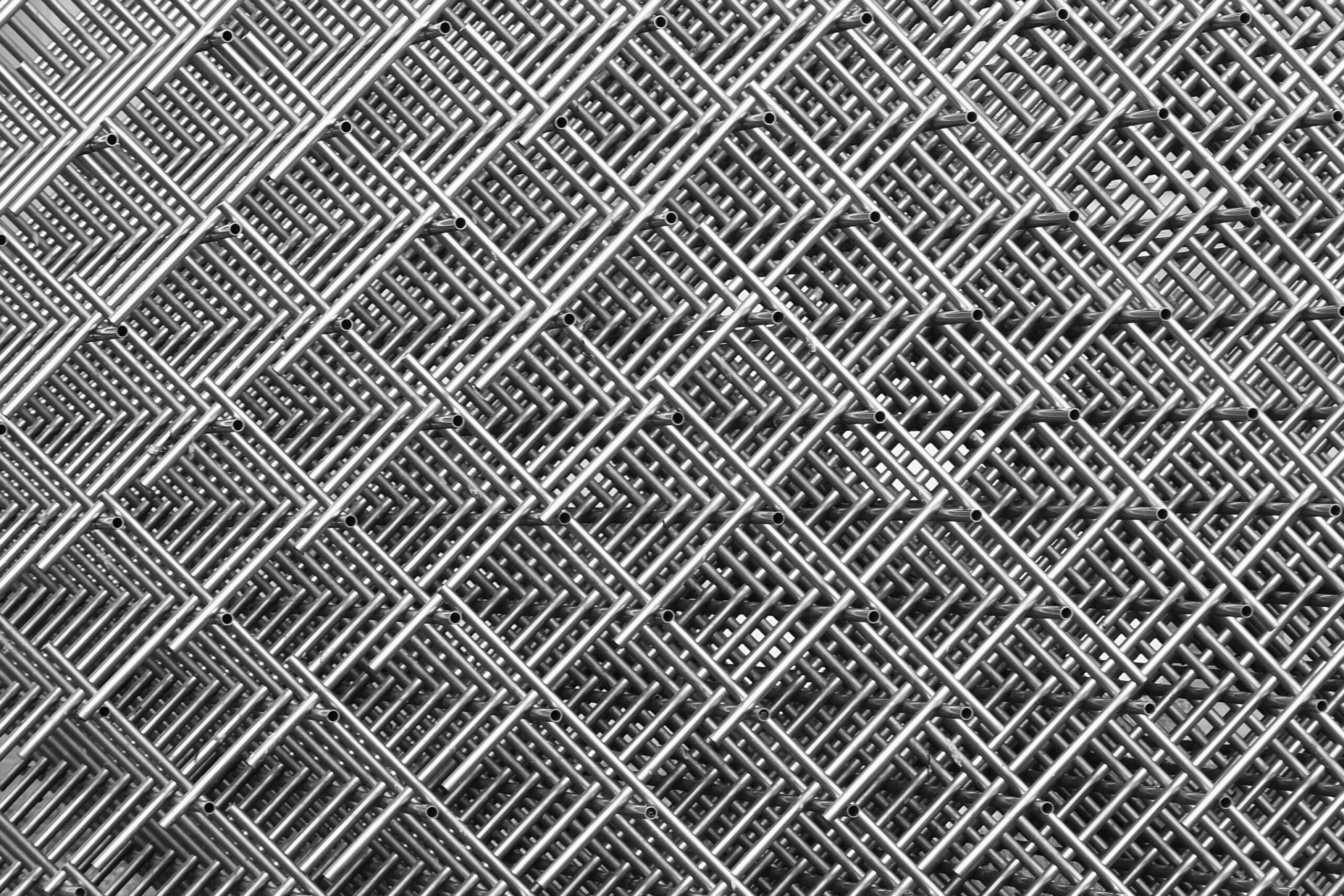

Overview of Ferritik Stainless Steel

Ferritik stainless steel, a type of stainless steel alloy, is known for its high chromium content and low carbon levels. This combination gives it impressive corrosion resistance and good strength, making it a popular choice in various industries.

Properties of Ferritik Stainless Steel

Ferritik stainless steel is magnetic and has excellent resistance to corrosion, heat, and stress cracking. It is also known for its formability and weldability, making it versatile for different applications.

2. Understanding Wear Resistance in Stainless Steel

Importance of Wear Resistance in Stainless Steel

Wear resistance is crucial for stainless steel as it determines how well the material can withstand abrasion, friction, and wear over time. This property is essential in applications where materials are subjected to harsh conditions and frequent use.

Factors Affecting Wear Resistance

Various factors influence the wear resistance of stainless steel, including its composition, microstructure, hardness, and the presence of other elements like molybdenum and nitrogen. Surface finish and treatment processes also play a significant role in enhancing wear resistance.

3. Comparative Analysis of FerritikStainless Steel with Other Types

Comparison with Austenitic Stainless Steel

Compared to austenitic stainless steel, ferritik stainless steel is generally more affordable and easier to form. However, it tends to have lower corrosion resistance and toughness but superior wear resistance in many applications.

Comparison with Martensitic Stainless Steel

Martensitic stainless steel is known for its high hardness and strength but may lack adequate corrosion resistance compared to ferritik stainless steel. Ferritik stainless steel typically offers better wear resistance and toughness in certain environments.

4. Factors Contributing to Ferritik Stainless Steel’s Superior Wear Resistance

Microstructure and Composition

The specific microstructure and composition of ferritik stainless steel, with its high chromium content and low carbon levels, contribute to its excellent wear resistance. This structure enhances the material’s ability to resist abrasion and maintain its integrity under friction.

Heat Treatment and Processing

Heat treatment processes and specific manufacturing techniques can further enhance the wear resistance of ferritik stainless steel. Through proper heat treatment and processing, the material can achieve optimized microstructures and surface finishes that improve its wear resistance properties.

5. Applications and Industries Benefiting from Ferritik Stainless Steel

Automotive Industry

When it comes to the automotive industry, Ferritik Stainless Steel shines like a shiny new sports car. Its superior wear resistance and corrosion properties make it a top choice for components like exhaust systems, trim, and grilles. With Ferritik Stainless Steel under the hood, cars can withstand the rough and tumble of daily drives without losing their shine.

Construction and Architecture

In the world of construction and architecture, Ferritik Stainless Steel is the unsung hero that keeps buildings looking sleek and modern. From structural elements to decorative finishes, this durable material stands the test of time against harsh weather conditions and wear and tear. Whether it’s a gleaming skyscraper or a stylish interior design feature, Ferritik Stainless Steel adds a touch of elegance that lasts.

6. Future Prospects and Innovations in Ferritik Stainless Steel Technology

Advancements in Alloy Development

The future of Ferritik Stainless Steel is looking brighter than a freshly polished surface. Engineers and researchers are constantly pushing the boundaries of alloy development to improve its strength, corrosion resistance, and overall performance. With new and innovative formulations on the horizon, Ferritik Stainless Steel is set to revolutionize industries from automotive to aerospace.

Emerging Trends in Wear-Resistant Coating

Say goodbye to scratches and scuffs with the latest trend in Ferritik Stainless Steel technology: wear-resistant coatings. These advanced coatings add an extra layer of protection, enhancing the already impressive durability of this material. From anti-fingerprint finishes to scratch-proof surfaces, Ferritik Stainless Steel is stepping up its game to meet the demands of modern applications.

Conclusion

In conclusion, Ferritik Stainless Steel is not just a metal, it’s a superhero in the world of materials. With its unmatched wear resistance and versatility, this shining star is set to brighten the future of industries far and wide. So, buckle up and get ready to ride the wave of innovation with Ferritik Stainless Steel at the helm!

The superior wear resistance of ferritik stainless steel makes it a valuable material in various industrial sectors where durability and longevity are paramount. As technology advances and research progresses, the potential for further enhancing the properties of ferritik stainless steel remains promising. With its proven track record and continuous innovations, ferritik stainless steel stands as a reliable and versatile option for applications requiring optimal wear performance.